7:20 pm

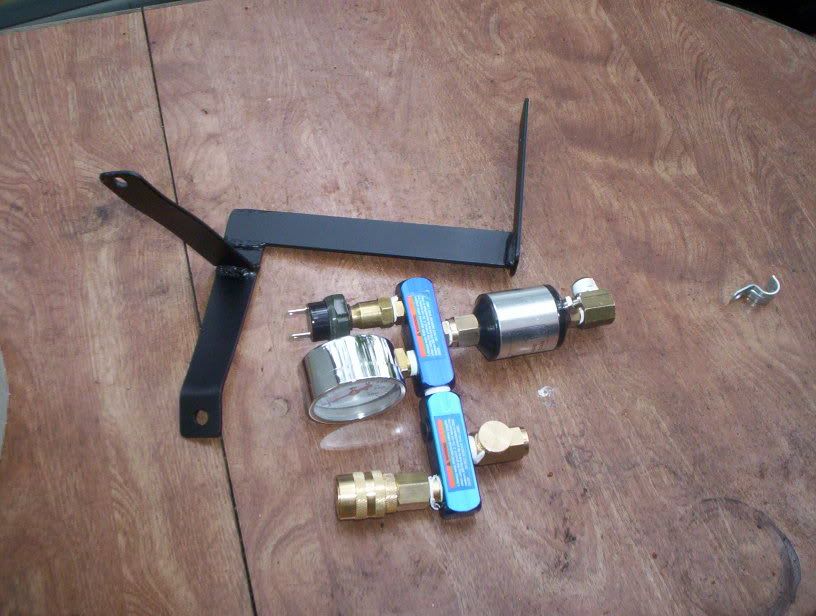

wow nobody doing any fab work? i finally got oba! i took a ac pump off a taurus and made some brackets to hold it in place. since it sits a little higher than the stock ac pump, i had to get a belt 1" longer than a tj belt. the yj's belt runs different than a tj. if i were to run in the stock yj configuration i would have to add an idler pulley. so i installed it in the tj way. made a little bracket to hold the oiler separator, pressure switch(90-120 psi), etc.

i also installed a toggle switch on the dash to operate it. im still not sure how the oil er is working since its designed to be on the high pressure side. it being on the intake is now under a little vacuum. man this thing really blows, in a good way! i think it will run air tools. i did have a few leaks in my bumper ,but there pretty good now not to bad for under a hundred bucks.

11:23 pm

"Justin" wrote: Nice Bob!!! 8)

Your skills amaze me. 😀

this was one of the easier tasks, pretty str8 forward. its funny how before you start something , its a little intimidating, then when your done , you say to yourself, that wasn't that bad . i hope i only have to use it for airing back up and not bead setting. o yes ,i know how to do that!(just easy on the starter fluid next time.) Justin ru still out for the Monday dear valley trip? i posted it here last week but got no response so i deleted it. its still happening.

2:22 am

"Dan-H" wrote: looks good !

Is this your checkvalve?

my check valve gets really hot so I threaded it directly into my tank so the tank would help dissipate heat. It seems to help.

i didnt know that the check valves get hot. is there some much resistance that it causes heat? i hope my air hoses that are close to the pump dont melt

1 Guest(s)

Offline

Offline